Services

Support & Technical Expertise

At Portsmouth Plastics, our service crew consists of highly trained professionals with deep-rooted knowledge in hydraulic extrusion blow moulding systems. Our team is ready to assist your operators and engineering staff whenever needed. Utilising remote access capabilities, we can monitor and troubleshoot machines in real-time—no matter where they’re located. We also collaborate closely with clients to organise tailored maintenance schedules and in-depth operator training programmes. This ensures your production line stays sharp, reliable, and consistently performs at peak capacity.

Production Optimisation & Audits

With over 30 years of experience in hydraulic blow moulding, we offer detailed production audits to help you get the most out of your machines. From cycle time analysis to energy efficiency and component wear assessments, we help identify problems, reduce downtime, and improve product quality.

Training & Operator Support

We provide hands-on training sessions for machine operators and maintenance teams, either on-site or remotely. Our goal is to ensure your staff can fully operate, manage, and troubleshoot your hydraulic blow moulding systems with confidence.

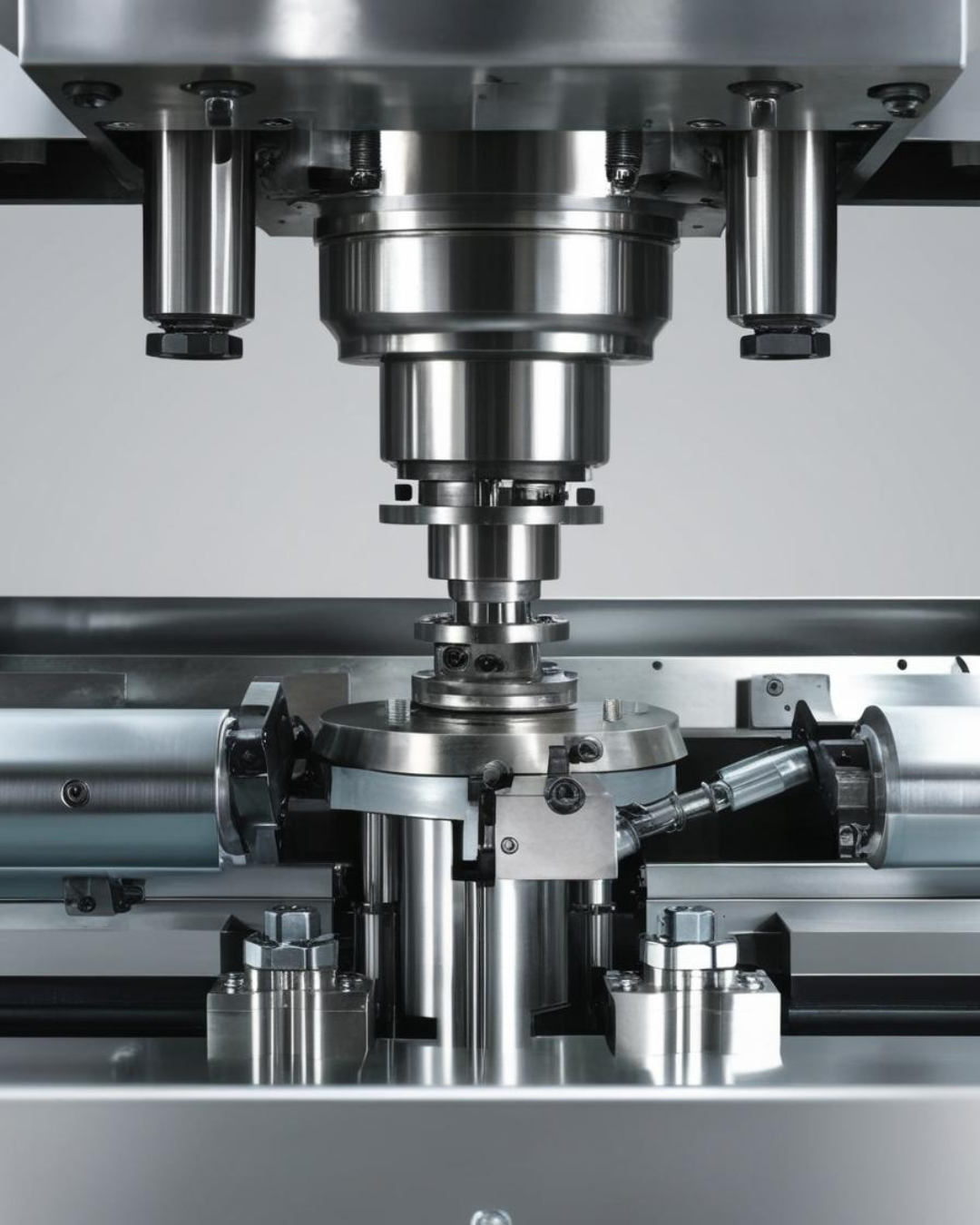

Hydraulic Blow Molding

Specialized Solutions

Integrated Systems

Programmable Logic Controller and Control Upgrades

Aging control systems and outdated electronics often limit the performance and longevity of extrusion blow moulding equipment. Sourcing legacy spare parts has become increasingly difficult across the industry. In response, Portsmouth Plastics has engineered its own advanced Portsmouth Plastics, combining robust software with cutting-edge hardware to revitalise older machines.

Operating with continuous extrusion or accumulation methods, our Portsmouth Plastics offers a smart, adaptable solution—compatible with all major platforms, which are designed for easy integration, it breathes new life into machines that still hold strong production value.

We’ve successfully implemented more than 50 control modifications over the past 7 years to our blow moulding machines and directly on-site at customer facilities. Our control upgrade ensures improved reliability, efficiency, and ease of operation.

Service and Spare Parts

At Portsmouth Plastics we pride ourselves on being able to respond quickly and efficiently to all your technical and process support needs.

Our team of experts is made up of highly qualified professionals who specialize in the processes and problem-solving for extrusion blow moulding machines. We offer support whenever it’s needed, including remote assistance, so we can monitor your machine from anywhere in the world. If necessary, our technicians can arrive at your facility with very little notice, ready to assist with urgent repairs or maintenance.

Additionally, we offer Preventive Maintenance Plans and training programs, ensuring your machines remain in top condition and your production stays at optimal efficiency.

Retrofit

Portsmouth Plastics provides tailored upgrade services for all types of our blow moulding systems. Our experienced technicians travel directly to client sites to perform on-location assessments, including precise dimensional analysis when reverse design is required. We specialise in engineering and delivering custom-built extrusion modules, converting machinery from single to double production formats, and implementing all necessary modifications to accommodate new container shapes or shifting output demands.

Safety and Refurbishing UKCA

At Portsmouth Plastics we offer complete refurbishing services for our blow moulding machines, ensuring it meets the latest standards and operates at peak performance. We handle complete overhauls either on-site or at our UK premises, tailored to customer specifications. Whether you need partial or full refurbishing, we provide the latest components and equipment, including both original and customized parts. We also offer the option to have your machine certified with UKCA certification, ensuring it meets the necessary safety standards and control requirements. In addition to refurbishing the machine, we can supply new equipment.